Die casting is a manufacturing process that can produce geometrically complex metal parts through the use of reusable molds, called dies. The die casting process involves the use of a furnace, metal, die casting machine, and die. The metal, typically a non-ferrous alloy such as aluminum or zinc, is melted in the furnace and then injected into the dies in the die casting machine. There are two main types of die casting machines - hot chamber machines (used for alloys with low melting temperatures, such as zinc) and cold chamber machines (used for alloys with high melting temperatures, such as aluminum). The differences between these machines will be detailed in the sections on equipment and tooling. However, in both machines, after the molten metal is injected into the dies, it rapidly cools and solidifies into the final part, called the casting.

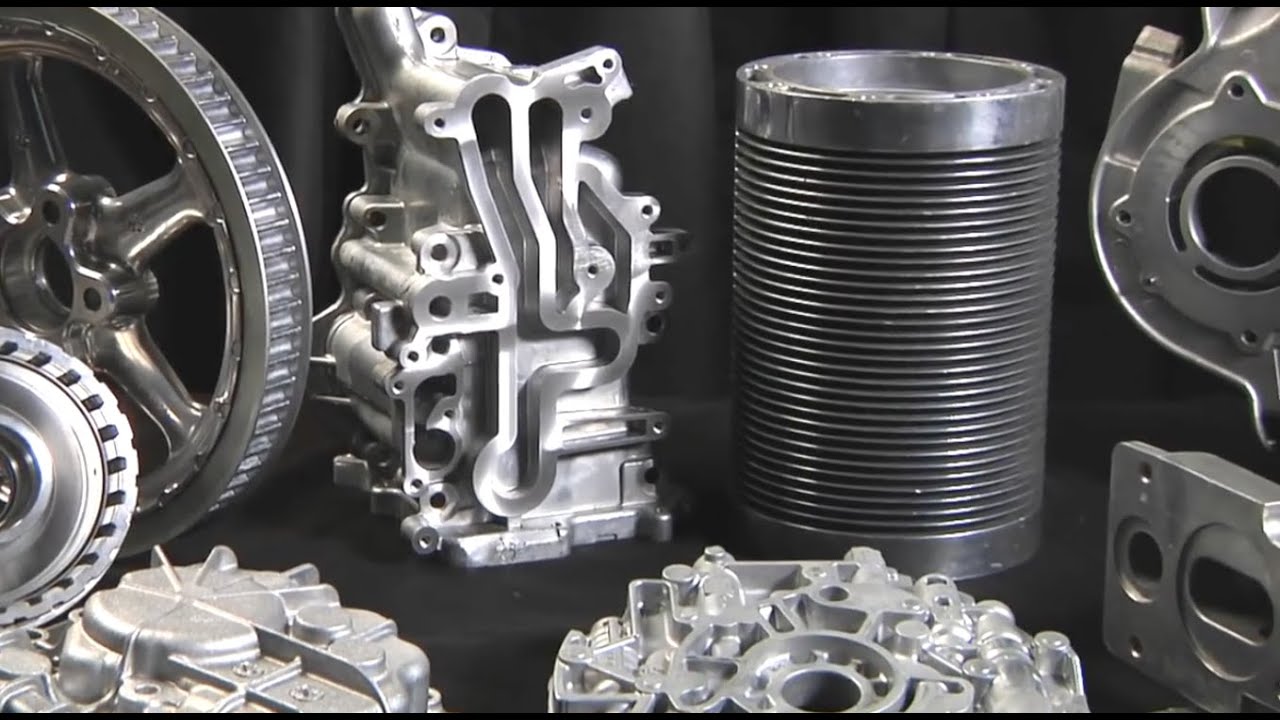

Die casting is a manufacturing process that can produce geometrically complex metal parts through the use of reusable molds, called dies. The die casting process involves the use of a furnace, metal, die casting machine, and die. The metal, typically a non-ferrous alloy such as aluminum or zinc, is melted in the furnace and then injected into the dies in the die casting machine. There are two main types of die casting machines - hot chamber machines (used for alloys with low melting temperatures, such as zinc) and cold chamber machines (used for alloys with high melting temperatures, such as aluminum). The differences between these machines will be detailed in the sections on equipment and tooling. However, in both machines, after the molten metal is injected into the dies, it rapidly cools and solidifies into the final part, called the casting. RCM INDUSTRIES TAKES US INTO THEIR FACILITY IS THIS SHORT EDUCATIONAL CLIP!

If you have questions or would like to talk about your invention head over to www.kcharltonindustries.com or email me at charlton.kurtis@kcharltonindustries.com. You can also find us on Facebook and Instagram. As a devoted listener we want to show our appreciation by providing you a link to secure two FREE MONTHS of Skill Share's Premium Membership! Our classes are free to the public and the membership will give you access to the skills you will need to bring your next project to life. IE Marketing, Design, Sales, Licensing, Patenting and much more. Get started with your class here!

0 Comments